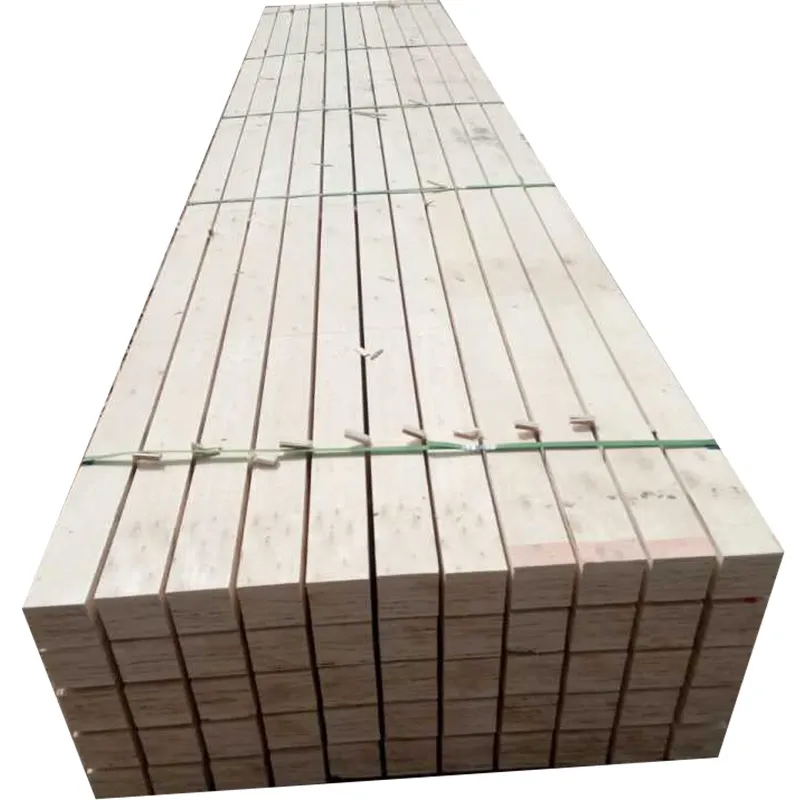

Building Construction Pine Poplar Hardwood Plywood Timber Beam Lvl Laminated Wood Planks

size: max length is 8m, max width is1.5m

core: poplar/combi/pine

glue: WBP /E1/E2

grade:AA, A,packing

use : make furniture or building use

LVL (Lamited Veneer Lumber):

Our company producing LVL for so many years to the market such as Europe, South America,Korea, North Africa, Middle East, and Southern Asia etc, with very good quality and more competitive price! Every month we export the plywood to these market with very huge quantity!

Please kindly feel free to contact us, believe that we will be your best supplier!

Production decription

| Brand | LVL Wood Beam |

| Length | As customer’s request |

| Width | As customer’s request |

| Thickness | 5mm-300mm |

| Material | Poplar, pine, birch,eucalyptus, hard wood or combine |

| Surface | sanding or no sanding |

| Density | 600kg/m3 |

| Glue | E1,E2, E0, WBP melamine |

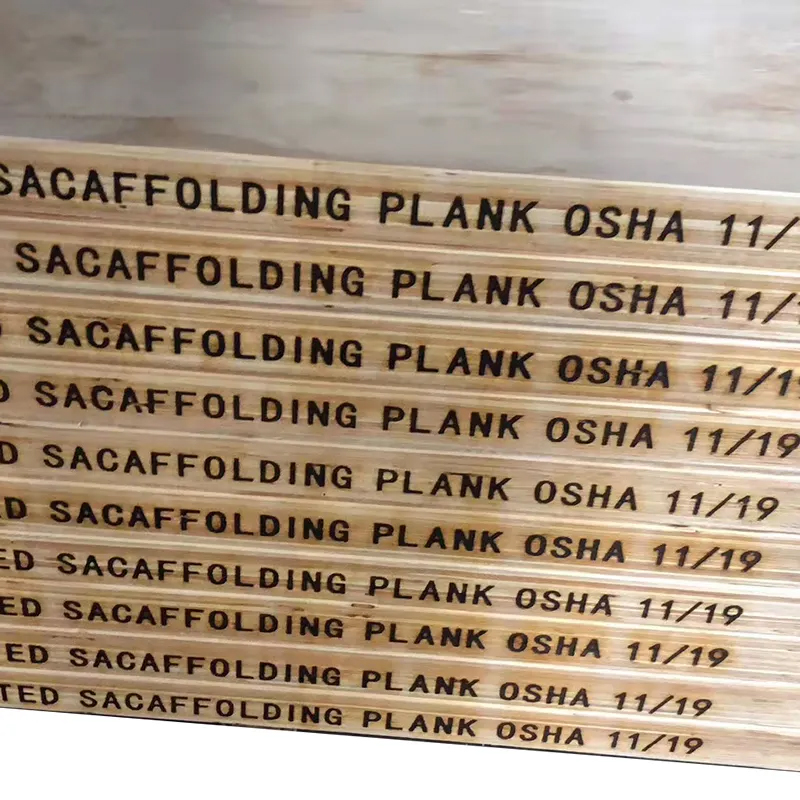

| Usage | Packing, construction, furniture,decoration,scaffolding board |

| Certification | ISO9001:2000 |

| Quantity | 25cbm within 20GP; 50cbm within 40HQ |

| Payment | T/T( 30% prepayment and the balance should be paid upon the copy of B/L)Or LC at sight |

| Delivery | Within 15 days after receipt of 30% of deposit by T/T /or L/C |

| Package | Pallet package with steel strip for strengthen |

| Feature | 1. Surface is smooth, exquisite 2. Strong screw holding 3. moisture-proof and easy–working ,easy-drill 4. Environmental friendly 5. Low formaldehyde releasing 6. High bending strength |

Pine: A Sustainable and Cost-Effective Choice

Pine is a softwood that is widely used in building construction due to its affordability and sustainability. It is known for its light color and distinct grain patterns, which add a natural and rustic charm to structures. Pine is readily available and easy to work with, making it a popular choice for framing, flooring, and wall paneling.

One of the advantages of pine is its dimensional stability, meaning it experiences minimal expansion and contraction when exposed to moisture and temperature variations. This characteristic makes pine suitable for areas with fluctuating environmental conditions. Additionally, pine can be treated with preservatives to enhance its durability and resistance to decay and insect infestation.

Poplar: Combining Strength and Flexibility

Poplar is another versatile material used in building construction. It is a hardwood with a fine texture and a pale yellowish-brown hue. Poplar possesses excellent strength-to-weight ratio, making it suitable for various structural applications. It is commonly used for manufacturing beams, columns, moldings, and interior trim work.

One of the notable properties of poplar is its flexibility, which allows it to withstand bending and twisting forces without breaking. This makes it ideal for applications that require resilience and durability. Poplar can also be easily painted or stained to achieve the desired aesthetic effect, making it a popular choice for interior finishes.

Hardwood: Durability and Elegance

Hardwood is renowned for its durability and natural beauty, making it highly sought after in building construction. With a wide range of species available, including oak, walnut, and cherry, hardwood offers various grain patterns, colors, and textures to suit different design preferences.

Hardwood is commonly used for flooring, cabinetry, furniture, and decorative elements. Its density and strength provide excellent resistance to wear and tear, ensuring longevity in high-traffic areas. Hardwood can be sanded and refinished multiple times, allowing it to retain its elegance and luster for years to come.

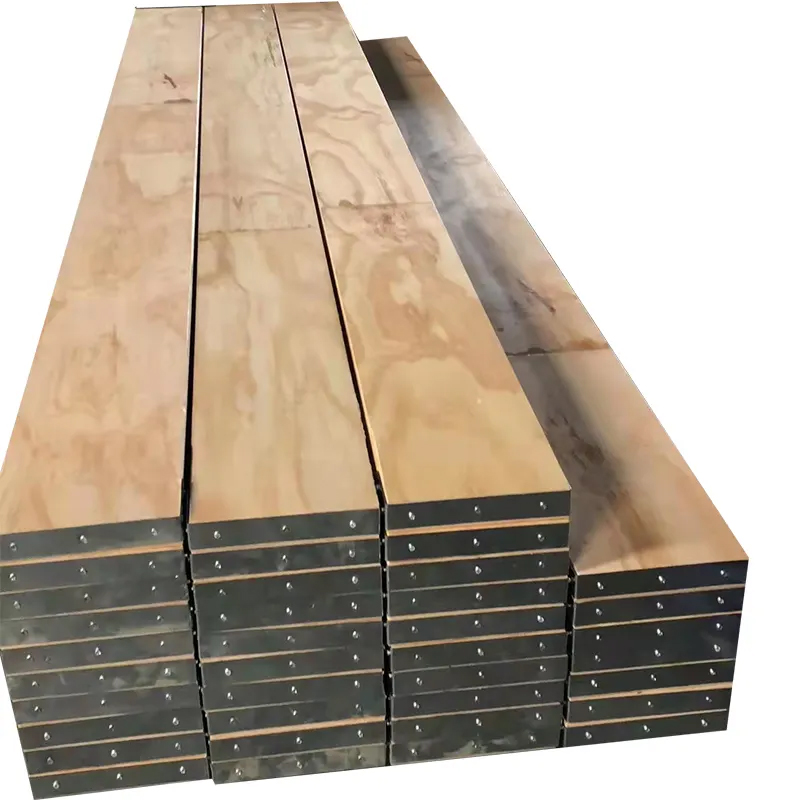

Plywood: Strength and Stability in Layers

Plywood is a composite material composed of thin layers of wood veneer glued together. This construction gives plywood exceptional strength and stability, making it suitable for a wide range of applications in building construction. The layers are oriented in alternating directions, which enhances its resistance to warping, shrinking, and cracking.

Due to its versatility, plywood is used for roofing, flooring, wall sheathing, cabinets, and furniture. It provides excellent dimensional stability and can be manufactured in large panel sizes, reducing the need for joints and increasing structural integrity. Plywood is also available in different grades, allowing builders to choose the appropriate quality for their specific requirements.

Timber Beam: Supporting Structures with Natural Strength

Timber beams have been used for centuries in building construction, and their enduring popularity is a testament to their strength and reliability. Timber beams are typically large, solid pieces of wood that provide structural support to roofs, floors, and walls. They are available in various species, including pine, oak, and Douglas fir.

Timber beamsprovide a natural and organic aesthetic to a building’s interior or exterior. They can be left exposed, showcasing their beautiful grain patterns and adding warmth and character to the space. Timber beams are often used in traditional or rustic architectural styles but can also be incorporated into modern designs for a unique touch.

The choice of timber species for beams depends on the desired strength, appearance, and budget. Pine beams are commonly used due to their affordability and availability. They offer adequate strength for many applications and can be treated to enhance their durability. Oak beams, on the other hand, are known for their exceptional strength and durability. They are often chosen for heavy load-bearing structures and can withstand the test of time.

Timber beams can be customized in terms of size, shape, and finish to meet specific design requirements. They can be solid, laminated, or engineered, depending on the structural demands and architectural vision. Timber beams can also be sculpted or carved to create intricate designs or decorative elements, adding a touch of elegance to the overall aesthetics of a building.